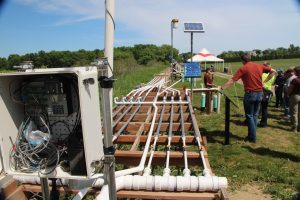

Soil scientist Satoshi Ishii demonstrates how bioreactors work.

Written by Jonathan Eisenthal

Kim Gorans , his dad, uncles, brother-in-law and cousins — 11 family members in all — work together raising turkeys and corn on their farm just south of Willmar. They are striving to make their land produce bountiful food and clean water.

Since 2006, Gorans’ farm site, close to Lake Kandiyohi, has been home to a bioreactor research project. A bioreactor is a filtration system set up at the edge of the farm field to filter tile drainage water. Microbes living on woodchips inside the bioreactor “eat” nitrate nitrogen.

Nitrates pose a compelling challenge for farmers. Nitrogen is a vital nutrient needed in the field to feed the crops. It can come from natural mineralization, previous crops that fix nitrogen such as soybean or alfalfa, manures, or commercial fertilizer. Nitrogen in the water soluble form of nitrates that have left the field have potential to harm the environment and drinking water.

“There is a lot of innovation going on at this farm, and the bioreactor is only one piece of this puzzle. We need to thank Kim and his family for hosting this research project here,” says Carl Rosen, director of University of Minnesota Department of Soil, Water and Climate. He is a co-principal investigator, along with Gary Feyereisen, a USDA-ARS engineer who has conducted bioreactor research for the past five years.

Bioreactor design

The bioreactor was initially designed by retired Prof. John Moncrief to work as a single chamber, filled with wood chips, which would denitrify the water.

In 2014, the design was updated and improved to make it over into eight different chambers where they could test four different treatments, each replicated twice, to compare and discover the most effective way of reducing nitrates. Microbiologist Mike Sadowski, environmental microbiologist Satoshi Ishii, both with the University of Minnesota’s Dept. of Soil, Water and Climan, and bioengineer Eshan Ghani all presented information about the project at a recent field day.

Farmer Kim Gorans

Farmer groups have donated upwards of a million dollars to this bioreactor project. Minnesota Corn Growers Association (MCGA), Minnesota Soybean Growers, Minnesota Turkey Growers and the Minnesota Agricultural Water Resource Center (MAWRC) have all supported the research.

Kim Gorans describes their farming operation as the quest to make their fields over into the perfect growth medium for their crops. In such a system there would be an ideal level of nitrates available to feed the growing crop — spoon fed when needed and in just the right amount for the plants to make use of it. He doesn’t want any flowing beyond his fields—it’s both an economic and environmental issue.

“We raise 60 million pounds of turkeys a year, in 60 turkey barns, and we crop 4,000 acres,” Gorans said. “We run our own feed mill and spread manure on 10,000 acres of our own land and other farmers who are our customers. Back in 2006, I was at some organic farming seminars and they were talking about turkey manure, poultry manure as an ideal organic fertilizer because of a slower release of nitrogen. It doesn’t hurt the earthworms and it’s got bacterial life in it. It’s got all the micro nutrients and the NPK (Nitrogen-Phosphorous-Potassium) isn’t that bad. It just didn’t make sense to me that we could have the most ideal fertilizer and we were made to treat it like toxic waste.”

Constantly improving

So the Gorans continually test and improve their fertilizer application and cultivation methods. They see the bioreactor as one more element in creating the perfect farm. In 2009, Gorans’ farm became the first Minnesota Discovery Farms site, a farmer-led nutrient research program which has grown to a dozen farm sites across Minnesota.

“Minnesota farm groups are putting about $500,000 a year into all of these (Discovery Farms) sites,” said Warren Formo, director of Minnesota Ag Water Resource Center. He oversees the

The experimental bioreactor at Gorans Farm splits the flow of tile drainage water into eight different channels in order to do four different replicated treatments, to see which reduces nitrates most effectively.

Minnesota Discovery Farms network.

“This investment from the farmers pays for the gathering of the data, the analysis of the water, interacting with farmers, doing outreach activities like this field day —that’s farmer check-off money. We’ve got sites all the way from Dodge County in southeast Minnesota all the way up to Norman County in northwest Minnesota. The key is that this should be farmer led. We ask the farmers what we should be monitoring for and have them lead the search for better agronomic practices. Farmers are skeptical of growing advice from non-farmers, but they are very receptive to learning from other farmers. There is competition among farmers — we all want to do better than our neighbors – -but we are not blind to what works. When farmers are shown data that something is an improvement they are willing to look at it.”

In addition to the farmer-derived funding, this bioreactor work is supported through MnDRIVE, “Minnesota’s Discovery, Research and InnoVation Economy,” an initiative of the Minnesota Legislature to fund research at the University of Minnesota that will have a direct impact on the state’s quality of life and its economy. Clean water is important from both angles. The University of Minnesota BioTechnology Institute won the grant from the MnDRIVE program.

Biostimulation and Bioaugmentation

In this new experiment design, two of the chambers house a typical woodchip-filled filtration chamber. Another treatment is labeled ‘biostimulation’ – the researchers have added a carbon ‘energy source’ to boost the activity of the microbes.

In Minnesota, a good deal of the tile flow happens when water temperatures hover in the 40s in the early spring and late fall. Under these conditions, the bacteria’s respiration process slows down and nitrate consumption falls to almost nothing.

Biostimulation with carbon can help that, but another strategy is called bioaugmentation. The researchers have been sampling and testing the bacteria they find in the bioreactor, literally millions of different species are present on the woodchip surface, in order to isolate individuals that perform well under low temperature conditions. They then grow up batches of these high performers and add them back, to see if this ‘bioaugmentation’ will increase the consumption of nitrates. The fourth treatment puts together both biostimulation and bioaugmentation, to see if the combination will provide a bigger boost.